The liners were only loosely installed into the block with hand pressure. The space between liner and block formed a large uninterrupted water jacket, which improved cylinder heat dispersal into the cooling system, as did the thin tubes of the liners. Rather than the cylinders being bored into the cast-iron block, separate thin-walled steel tubes were inserted into a hollow block. The distinctive, and unusual, feature of the engine was its use of wet liners to form the cylinders. Had the tractor been built at Ford, Dagenham as originally intended, it is likely that the engine would still have been designed around the whitemetal bearings that Ford continued with on small car engines throughout the 1950s. Several replacement bearing shells were expected to be fitted before the crankshaft required re-grinding. Rather than re-metalling the bearing journals and hand-scraping a new bearing surface to fit the crankshaft, these bearings were disposable after use. It was one of the first mass-production engines to use thin-wall bearings: a steel shell faced with whitemetal bearing material. This avoided the need for costly hand-fitting during assembly and also simplified replacement in service. In some aspects it was advanced for its day, particularly in its use of components such as pistons being pre-graded into standardised sizes and marked as such. Cylinder block and crankcase were one piece cast iron, as was the cylinder head.Ĭonstruction of the engine would be regarded as typical for the 1950s, although this engine was developed in the late 1940s and its lineal derivatives, the Triumph straight-four and straight-six engines, would remain in production into the 1970s. Conventional overhead valves were driven from a camshaft mounted in the side of the cylinder block via vertical pushrods and adjustable rockers. A compression ratio of 5.77:1 reflected the era's low octane fuel. The engine was undersquare(long stroke), favouring the tractor's need for torque over horsepower. It was a petrol powered four-cylinder engine with a bore of 80 mm and stroke of 92 mm, for a total capacity of 1,850 cc. The first TE20 model used a Continental Z-120 petrol engine, but the TE-A20 and later models used a new engine developed by Standard. Ford however was unwilling and it was Standard which was to build the tractors at Banner Lane. Afterwards, Ferguson wished to continue this arrangement with an improved TO20 tractor (for "Tractor Overseas") and also a TE20 (for "Tractor England") to be built by Ford's plant at Dagenham. With peace in 1945, this huge factory then stood empty.ĭuring the war, Ford had built tractors for Ferguson in Detroit. From 1939 this factory produced Bristol Hercules engines, an air-cooled radial engine, with Bristol's typical sleeve valves. The engine's origins lay in the wartime production of Bristol aero engines at the new Banner Lane shadow factory, operated by Standard in Coventry. The water-cooled overhead valve engine featured novel advances for an immediate post-war design, which included thin-wall bearings with replaceable shells and loose-fitted wet liners.

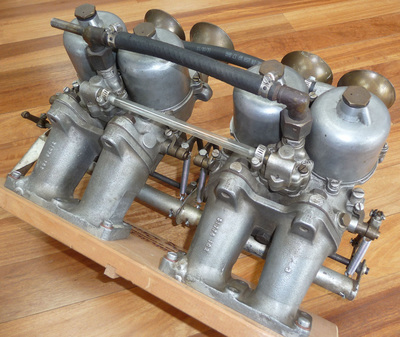

Triumph tr3a auc 768 su carburetors photo high def series#

Later it was successfully used in Standard's popular early generation Triumph TR series sports cars.

Originally developed concurrently for passenger car use and for the Ferguson TE20 tractor, it was widely used for Standard passenger cars of the 1950s, most notably the Vanguard. The Standard wet liner inline-four engine was a 2,088 cc inline four cylinder petrol engine produced by the Standard Motor Company. Petrol (gasoline), TVO, lamp oil (variant engines, not multifuel) 1991 cc Triumph version fitted in a 1961 TR3A

0 kommentar(er)

0 kommentar(er)